Types of Scrubber

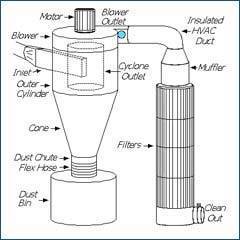

1. Scrubber Cyclone Type

We are engaged in manufacturing a wide range of cyclone system manufacturer and cyclone Type Dust Collectors. These multi cyclone dust collector, industrial dust collector that we offer are ideal for removing particulate from in plant air efficiently and in a cost effective manner.

Our range is also available in customized range and are packaged as per the client requirements. These flawless gamut of dust collector like industrial dust collector and cyclone dust collector finds application for Cement Manufacturing Plant,Wooden Working,Material Grinding Process,Buffing Rock Crushing etc.

Features:

- Exceptional Quality

- Hi-Performance

- Cost Effective and Compact Design

- Low Power Requirement

2. Scrubber Venturi Type

Wet Scrubber manufactured by us is specially designed to control pollution.In a Wet Scrubber, the pollutants are brought into contact with the cleaning liquid by spraying the liquid, or by other methods so as to remove the pollutants.

It is widely accepted by our clients for its flawless quality. This can be many type depending up on application and requirement.

Applications:

- Power Plants

- Chemical

- Pharmaceutical

- Foundries

- Cement Engineering

Features:

- Long lasting

- Great strength

- Very durable

- Easy to install

- Low maintenance

3. Wet Packed Bed Scrubber

1. Overview:

A wet scrubber for commercial kitchens is an air pollution control device designed to remove grease, oil vapors, particulate matter, and odorcausing compounds from the exhaust stream before it is discharged into the atmosphere. In bulk cooking, heavy smoke is generated due to high oil usage, continuous frying/grilling, and high-temperature cooking — this smoke contains:- Fine oil mist particles

- Fine Carbon particles

- oil odor

- Moisture and heat

2. Construction:

A typical commercial kitchen smoke-washing wet scrubber unit has the following components: A. Housing & Frame B. Inlet Section C. Scrubbing Chamber D. Water Circulation System E. Blower or Exhaust Fan3. Working Principle:

- Smoke enters through the inlet duct.

- Pre-filter / Baffle Filter stage traps larger grease/oil particles.

- Spray nozzles produce fine droplets that collide with smoke particles and soluble gases, washing them out of the airstream.

- Distribution Plates to ensure maximum contact between water and smoke.

- Mist eliminator removes excess water carryover.

- Clean air is exhausted via a blower to the chimney.

- Grease and contaminants settle in the water sump and are removed periodically.

4. Applications:

- Commercial kitchens in hotels, restaurants, food courts, banquet halls

- Industrial kitchens in factories, military bases, railway catering units

- Community kitchens for religious institutions, large event catering, hostels

- Food processing plants (frying lines, snack production)

5. Advantages / Uses:

- Removes visible smoke and oil mist from kitchen exhaust

- Reduces fire hazard by removing combustible grease from ducts

- Minimizes odor from cooking

- Meets environmental norms for air quality discharge

- Improves hygiene and cleanliness in surrounding areas