Cyclone Dust Collector

Most cyclone collectors never operate at peak efficiency. In order to reach maximum efficiency, all the factors mentioned above need to measured precisely and the cyclone manufactured to the specifications based on those measurements. If designing a new system, these measurements can be estimated closely with a knowledgeable engineer and precise measurements of duct length runs and sizes.

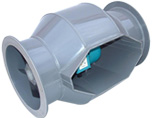

Cyclone Dust Collectors have commodious drums, conical shaped. They have metal tubes dusted over to top for suction of the impure air surroundings. The system is designed as such that the force running inside can be formulated according to the ideals of dust capacity restoring, depending on factors such as height to width ratio, Fan curve, water pressure drop and diameter inside. The in volute diameter is a prior part of cyclone dust collection system. It initiates the cyclonic action of the dusty air that enters in through the metal ducts. This allows the clean air vortex to escape exclusively.

Dirty air enters the Cyclone tangentially and centrifugal force moves the particulate against the cone wall, out of the airstream, to a storage unit.Clean air exhausts out of the Cyclone. Choose a Cyclone when collecting large particulate—use as a stand-alone collector or as a pre-filter to reduce the dirt loading on higher efficiency filter systems.Designed specifically for harsh, industrial environments, cyclone separators operate in applications generating heavy particulate and high temperatures. This design integrates a helix into the inner cylinder. This design reduces inlet turbulence common with conventional cyclones and speeds the creation of the centrifugal airflow.Greater centrifugal airflow improves particle separation and increases collection efficiency.